Contact us today for your Free Quote

Food waste and its packaging remain among the most common waste streams across workplaces including offices, hospitality venues, retail, and food service. But not all packaging is created equal. What looks recyclable or compostable may behave very differently once it enters the waste system.

This guide breaks down the main types of food packaging, explaining where they really belong, and highlights how contamination such as leftover food and grease can disrupt recycling. Our aim is to help businesses make informed, practical choices that support both sustainability goals and operational efficiency.

Why Food Packaging Matters

According to the latest WRAP data, total Food Waste produced in the UK in 2021 reached 10.7 million tonnes across households, hospitality, retail, manufacturing, and farms. Households alone produced around 6.0 million tonnes of food and drink waste in 2022.

A separate review suggests that 4.4 million tonnes of this could have been avoided, demonstrating how important both behaviour change and sustainable packaging design are for waste reduction.

For businesses, packaging choices do not just impact environmental outcomes. They also affect waste contamination rates, recycling performance, and long-term waste related costs.

Packaging Types and What They Mean in Practice

Below is a breakdown of common food packaging types, how they behave in the waste system, and what we recommend based on Bywaters’ experience working with thousands of London organisations.

1. Soft Plastics (Films, Wrappers, Pouches)

Soft plastics include items such as crisp packets, salad bags, bread bags, cling film and flexible food pouches.

Are they recyclable?

Soft plastics are technically recyclable, but not through standard mixed recycling streams. They require specialist processing and are easily contaminated by food.

In the UK, soft plastics are still not widely accepted in household recycling collections. WRAP and the UK Plastics Pact advise that flexible plastics should be taken to specific supermarket collection points where available to be recycled, and only when clean and uncontaminated.

Moreover, like all packaging, soft plastics are extremely vulnerable to food or grease contamination (crumbs, oils, moisture). This contamination affects it’s recyclability and often reduced its material quality. That’s especially problematic for businesses that generate residual food or oily waste.

Bywaters recommendation

- Avoid soft plastics whenever possible (especially for greasy, messy or perishable foods).

- If absolutely necessary, prioritise designs intended for specialist take-back or collection schemes.

- Where soft plastics are used, ensure clear staff guidance: avoid “wish-cycling” (i.e. placing every film in specialist recycling container), and direct contaminated items to General Waste or appropriate disposal routes.

2. Cardboard & Paper-Based Packaging

Paper-based food packaging includes items such as pizza boxes, paper bags and paper plates. Some takeaway boxes and sandwich wedge boxes look like cardboard, but many contain a plastic lining that prevents them from being recycled, even when clean.

Are they recyclable?

Yes! When clean!

Cardboard has one of the highest recycling rates in the UK, and when uncontaminated, it is an excellent, circular material.

However:

- Grease, sauces, and oils render paper unrecyclable

- A paper plate, cup, or box with visible food residue should go to General Waste or Food Waste (depending on your site’s process)

Example:

A clean paper plate? Recyclable.

A greasy paper plate? Not recyclable.

Why contamination matters

Once fibres absorb grease, the paper cannot be pulped properly. One contaminated, item can spoil a whole batch.

Bywaters recommendation

- Choose cardboard only when the product won’t heavily absorb grease

- Encourage staff to scrape leftovers into Food Waste bins before disposal

- Opt for water-based coatings rather than plastic linings

3. Biodegradable & Compostable Packaging

These include PLA cups, compostable cutlery, biodegradable bags, and plant-fibre boxes.

Are they sustainable?

The answer is: it depends.

These products only break down in industrial composting conditions, not in mixed recycling streams, and not in General Waste.

Common misconceptions

- They are not recyclable

Compostable and biodegradable materials contaminate plastic recycling streams, but they are recyclable in the correct waste stream. - They do not break down in landfill

Without oxygen and controlled heat, they behave similarly to normal plastics, and will not fully breakdown.

Contamination insight

Food Waste is not a harmful contaminant to the Compostable Waste stream as it is processed in a similar way, and will breakdown in less time than compostable items will. However, this is not the case the other way around. Compostable Waste is considered a contaminant to the Food Waste stream as it breaks down over a longer timeframe than food items.

Bywaters recommendation

- Only use compostable packaging if your site has a dedicated Compostable Waste stream

- Avoid mixing compostables with standard plastics

- Don’t assume “compostable” = better. Often recyclable cardboard or rigid plastics have a lower carbon footprint

- Opt for reusable containers to avoid producing waste at all

4. Composite & Mixed-Material Packaging

Think of:

- Coffee cups with plastic linings

- Cardboard pizza boxes with wax or film windows

- Paper and plastic glued together

Are they recyclable?

Generally, no.

Mixed materials are difficult to separate mechanically. Even if one layer is recyclable, the combined product is not.

Items made of composite materials are only recyclable through specialise waste streams. For example, coffee cups can only be recycled through a dedicated Coffee Cup waste stream.

Contamination insight

If there is a specialist waste stream for these composite materials, food residue can contaminate the waste stream, making it harder to recycle these already hard to recycle items.

Bywaters recommendation

- Switch to single-material packaging where possible

- If composite materials are unavoidable, look for easily separable components (e.g., removable lids, windows)

5. Rigid Plastics (Tubs, Bottles, Containers)

These include salad boxes, yogurt pots, and microwaveable trays.

Are they recyclable?

Yes, when rinsed!

Rigid plastics such as PET, HDPE and PP are widely recyclable across the UK.

Contamination insight

Unlike paper, plastics can be rinsed and recycled even if they previously contained food.

A quick rinse is enough to prevent contamination in the recycling stream.

Bywaters recommendation

- Choose clear PET where possible (highest recycling value)

- Encourage staff to rinse containers before disposal

- Avoid unnecessary colourants or black plastic (as sorting equipment at the MRF cannot detect them)

Why Contamination Changes Everything

Even the best packaging can’t be recycled if it’s heavily contaminated.

For example:

- A paper plate → recyclable when clean, not recyclable when greasy

- A plastic container → recyclable only once rinsed

- A compostable cup → only recyclable if processed through industrial facilities

Recent WRAP data from 2024 indicates that in a sample of input material at MRFs, 16.6% was contamination, demonstrating how common incorrect items or residue are in recycling bins.

This leads to higher disposal costs, lower recycling performance, and increased emissions.

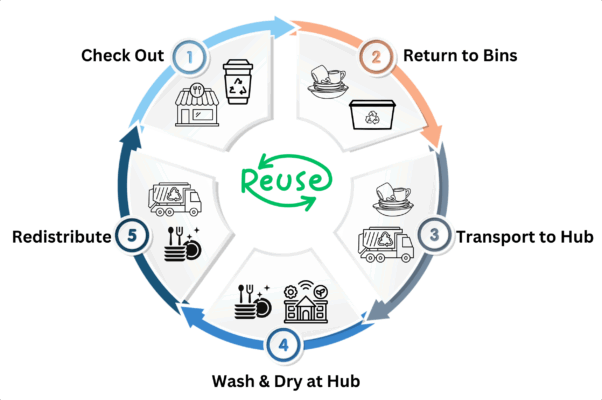

6. Reusable Solutions

As more organisations look beyond single-use packaging, reusable systems are becoming one of the most effective and reliable ways to reduce waste at source. Many workplaces already have the right infrastructure to support reusables, especially those with dishwashers, commercial kitchens, or on-site catering operations.

Why reusables matter

Reusable solutions removes the need for single-use packaging, and the unnecessary waste generation that comes with it. This approach typically has a lower carbon footprint over its lifetime and significantly reduces contamination issues in recycling streams.

Examples of reusable systems

Modern reuse models vary, and many can be adapted to office, hospitality or food-service settings:

- Dishwasher-supported reusables

Workplaces with kitchens can switch to washable plates, bowls, cups and cutlery. Once rinsed and cleaned, these cycle back into use without creating waste. - Closed-loop container systems

Services like Reuser Club and ClubZero offer returnable takeaway containers that are collected, washed and redistributed. These systems are ideal for staff canteens, food courts or sites with steady food traffic, ensuring reusable items stay within a controlled loop. - Reusable food-to-go solutions

Durable, washable takeaway boxes such as those offered by EcoToGo can replace disposable meal containers in cafes and canteens. Customers simply return them after use, and the operator cleans them onsite for future service.

When reusables work best

Reusable systems are most effective when a site has:

- Access to dishwashing facilities or commercial cleaning services

- A controlled environment such as an office, corporate campus, university, food market or canteen

- Clear processes for returning, washing and redistributing containers

- Staff engagement and simple instructions to reduce losses

Bywaters recommendation

If your site has the ability to wash and reuse items, reusables should be the first-choice option. They reduce waste, prevent contamination, lower long term procurement costs and support a circular approach to food service. For businesses looking to start small, pilot programmes or closed-loop takeaway systems can be an easy and impactful first step.

7. Emerging Packaging Materials: Seaweed Based Alternatives

Seaweed based packaging has gained significant attention as a low impact alternative to traditional plastics. Innovators in this space have developed materials made from seaweed and plants that are naturally biodegradable, plastic free and capable of breaking down without industrial composting conditions. Seaweed grows quickly, does not require freshwater, fertilisers or agricultural land and can absorb carbon as it develops. This gives it a strong environmental profile compared with petroleum based packaging. Early lifecycle assessments indicate that certain seaweed coated containers can reduce embodied carbon emissions by up to 79 percent compared with conventional plastic packaging and by around 39 percent compared with PLA coated board.

Other emerging solutions within the seaweed packaging sector include water soluble films, coated takeaway containers and flexible alternatives designed to replace hard to recycle single use plastics such as condiment sachets and food to go wraps. These formats are particularly promising for applications where lightweight packaging is required.

Although the environmental benefits are compelling, seaweed based packaging remains at an early stage of commercial adoption. Availability is still limited, costs are higher than standard materials and disposal routes are not yet consistent across the UK. As with all emerging materials, it is essential that organisations confirm the appropriate end of life pathway, since waste facilities may process seaweed based products differently depending on their composition.

So, What Should Businesses Choose?

Here’s a simple hierarchy:

Best choices

- Switching to reusable alternatives where possible

- Single-material packaging

- Recyclable rigid plastics (PET,PP)

- Clean cardboard/paper (where grease is minimal)

Use with caution

- Soft plastics

- Composite packaging

- Compostable materials (only if you have the right waste stream)

- Grease-absorbing paper packaging

Bywaters’ Perspective

At Bywaters, we support businesses in making practical, evidence-based decisions about packaging. Our sustainability team regularly reviews materials, contamination patterns, and end-market conditions to help clients choose options that:

- Reduce environmental impact

- Keep recycling streams clean

- Improve segregation on-site

- Lower overall waste management costs

We also offer site assessments, training, and AI-powered waste audits to help teams understand which items are key contaminants and how to address them.

Final Thoughts

There is no perfect packaging material, but there are better choices depending on your food offering and your onsite waste streams.

By focusing on reusable alternatives, single materials, reducing contamination, and avoiding unnecessary complexity, businesses can significantly improve recycling rates and make a measurable impact on sustainability.

More posts:

Valentine’s Day: History, Tradition, and Its Modern Impact

This post traces the evolution of Valentine’s Day from ancient Roman rituals to a global commercial event. It highlights the holiday’s hidden environmental impact and offers a guide to celebrating sustainably through “Circular Romance” and waste reduction.

Read morePlastic Recycling: Why Are Some Types Harder to Process Than Others?

Some plastics recycle easily, while others are difficult or impractical to process at scale. This article explains why material type, packaging design, contamination and recycling infrastructure all play a role, and what businesses can do to improve plastic recycling outcomes in the UK.

Read moreThe Ultimate Guide For a Sustainable School and University

Download The Ultimate Guide For a Sustainable School or University. Get the roadmap to cut costs, reduce your carbon footprint, and boost your ESG profile with 5 core pillars.

Read more