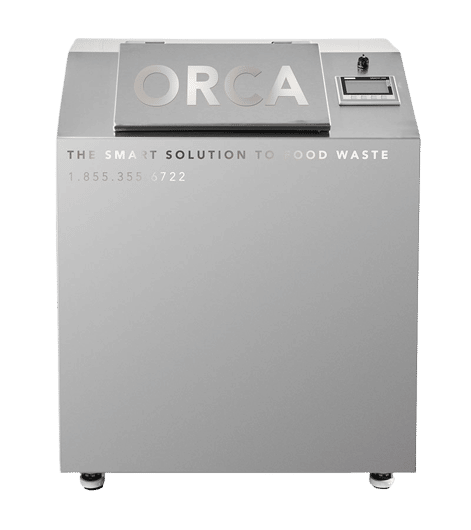

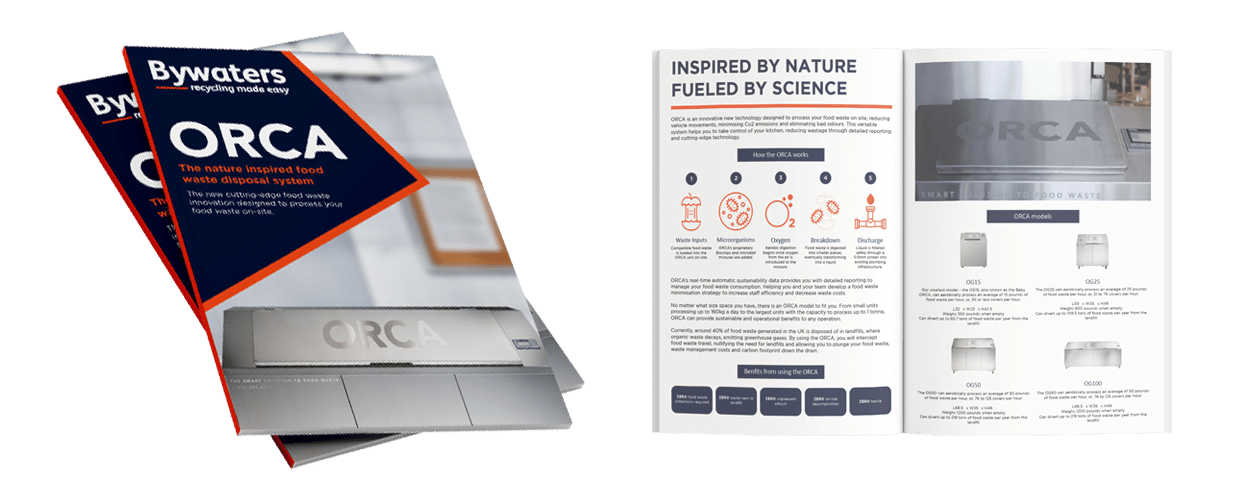

If your facility produces plenty of food waste the ORCA is the ideal solution for you. With various sizes, the orca can fit in compact kitchens or large waste rooms.

The ORCA negates the need for waste transportation, taking pollution out of the picture and saves you from further waste management costs.