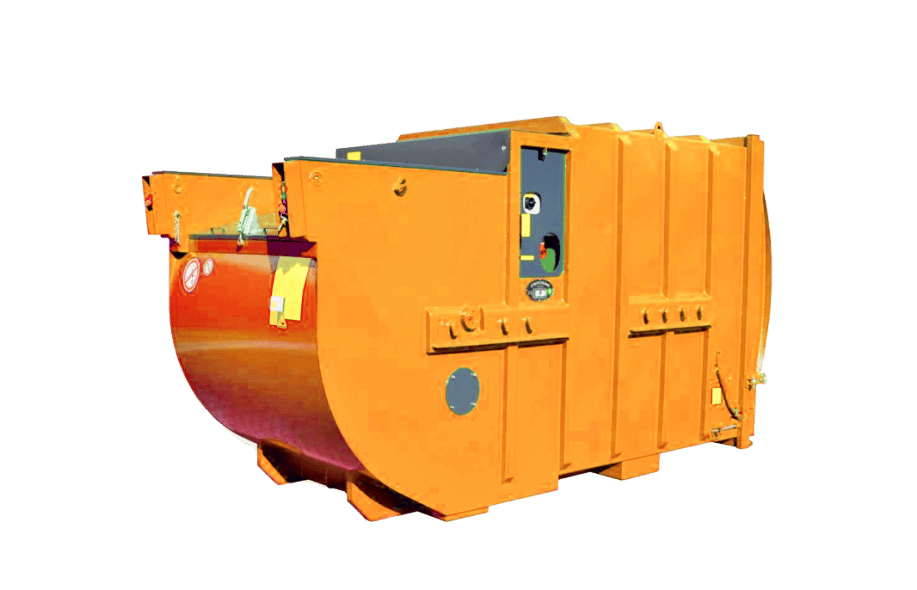

Using our compactor hire service limits the amount of storage space you need onsite. Able to hold large amounts of waste, a compactor will also reduce the number of trips you need to make back and forth to empty the container, saving time, money and reducing your business’s carbon footprint.